10KV CLASS THREE PHASE OIL IMMERSED TRANSFORMER

- Home

- Product

10KV CLASS THREE PHASE OIL IMMERSED TRANSFORMER

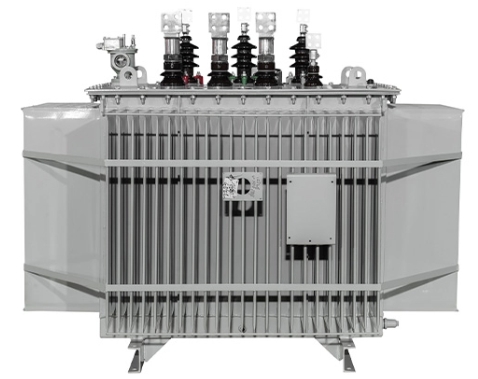

The 10kV three-phase oil-immersed distribution transformer is a critical component in power distribution networks and industrial power systems. Featuring a compact design with aesthetic appearance, it offers low noise operation and excellent overload capacity. Available in hermetically sealed or conservator tank types, this transformer is ideal for various applications including plants, mines, petrochemical facilities, and agricultural power systems. Its robust construction ensures reliable performance even in environments with oil contamination or chemical exposure. With high efficiency and durable design, it provides stable voltage transformation from 10kV to low-voltage levels, making it an essential solution for modern power distribution requirements.

-

Precise Voltage Regulation & Step-Down Performance

Our 10kV oil-immersed transformer delivers exceptional voltage regulation (±2.5% tolerance), efficiently stepping down high voltage (10kV) to safe low voltage (400V) levels. With 98.5% efficiency rating (per IEC 60076), it minimizes energy waste while ensuring stable power for residential, commercial, and industrial applications. -

Enhanced Electrical Isolation

The transformer provides complete galvanic isolation between primary and secondary windings, protecting end-user equipment from voltage surges (withstands up to 95kV impulse voltage). -

Safety to Electrical Appliances

High voltage power supply and fluctuation in voltage are the major reasons for the occurrence of electrical shocks and electrical hazards. It can cause short circuits, damage to electrical appliances, damage to property and life, and fire. The distribution transformers help in supplying consistent and safe voltage for the functioning of electrical appliances. It minimizes the risk of electrical hazards and offers safety to both appliances and life. -

Energy Loss Reduction Technology

Incorporates low-loss design (no-load losses <0.8%, load losses <1.2%) with optimized magnetic flux distribution. Reduces transmission waste by up to 40% compared to conventional models, verified by ISO 9001-certified testing.

| Type | Three Phase Oil-immersed Distribution Transformer |

|---|---|

| Model | S11~20 |

| Installation | Outdoor |

| Altitude | ≤1000m |

| Rated Power | 630KVA or others |

| Cooling Method | ONAN |

| Primary Voltage | 10KV |

| Secondary Voltage | 400V or others |

| Rated Frequence | 50/60HZ |

| Insulation oil | Mineral oil |

| Tapping Range | ±2×2.5%/±5% |

| Temperature rise (℃) | 65 |

| Connection Group | Dyn11/Yyn0 |

| Total weight (kg) | 1700 |

-

Urban Power Distribution Networks

Widely adopted in city substations and residential complexes to step down 10kV to 400V for daily consumption. The oil-cooled design ensures silent operation (≤55dB) ideal for densely populated areas while meeting strict urban safety regulations. -

Industrial Power Systems

Essential for manufacturing plants, mining operations and assembly lines requiring stable medium-voltage distribution. Its 150% overload capacity reliably supports heavy machinery startups and production peak loads. -

Renewable Energy Integration

Commonly installed in solar/wind farms as grid-connection transformers. Special anti-corrosion treatment protects components in coastal/high-humidity environments, maintaining 98% efficiency despite renewable power fluctuations. -

Rural Electrification Projects

Perfect for remote villages due to minimal maintenance requirements. Operates reliably in extreme conditions (-30°C~50°C) with automatic voltage regulation (±3%) for areas with unstable grid supply. -

Critical Infrastructure Support

Deployed in hospitals, data centers and transportation hubs where power continuity is vital. The hermetically sealed tank prevents oil leakage, achieving IP55 protection for indoor/outdoor installations.

-

Transportation

Ensure the transformer is securely fastened during transport to prevent movement or tipping. Use appropriate lifting equipment and avoid impacts or tilting beyond 15°. Protect from rain and mechanical damage. -

Deliverable Check

Upon receipt, inspect the transformer for physical damage, verify nameplate data, and check for missing accessories. Report discrepancies immediately. -

Storage

Store the transformer in a dry, ventilated area, away from corrosive substances. If stored outdoors, cover with waterproof material and elevate to prevent moisture ingress. -

Installation Environment Requirements

Install on a level, vibration-free foundation. Ambient temperature: -25°C to +40°C. Altitude ≤1000m. Avoid locations with excessive dust, corrosive gases, or risk of flooding. -

Electrical Installation

Connect primary and secondary cables according to the wiring diagram. Ensure all terminals are clean and tight. Ground the transformer as per local electrical codes. -

Common Components

Main tank, conservator (if applicable), bushings, tap changer, oil level gauge, thermometer, pressure relief device, and grounding terminals. -

Common Operation

Regularly monitor oil level, temperature, and load. Operate tap changer only under no-load conditions. Keep the area around the transformer clear. -

Fuse Installation

Install fuses on the low-voltage side as per rated current. Ensure correct fuse type and secure mounting. -

DC Resistance

Measure winding DC resistance before commissioning. Values should match factory test reports. Significant deviation may indicate internal faults. -

Pressure Resistance

Perform insulation resistance and withstand voltage tests as per standards before energizing. Ensure all test results are within specified limits. -

Transformer Ratio

Verify the voltage ratio using a transformer turns ratio tester. Results should conform to nameplate values. -

Power-on Operation

Confirm all connections and safety checks are complete. Power on the transformer with no load, monitor for abnormal noise, vibration, or leakage. Gradually apply load. -

Power-off Repair

Disconnect all power sources and ground the transformer before any maintenance. Wait for the transformer to cool before opening covers. -

General Maintenance

Inspect oil level, color, and dielectric strength regularly. Clean bushings and check for leaks. Tighten connections and check protective devices. -

Component Maintenance

Service tap changers, relays, and gauges as per manufacturer instructions. Replace gaskets and seals if oil leaks are detected. -

Component Replacement

Use only approved spare parts. De-energize and isolate the transformer before replacing bushings, gaskets, or other components. -

Transformer Troubleshooting

Common issues: overheating, abnormal noise, oil leakage, or tripping. Investigate causes such as overload, short circuit, or insulation failure. Consult technical support if needed. -

Table of Tightening Torque